LEANTRANSFORMATION

Even the best companies can become better by adopting a continuous improvement mindset.

Every year, your customers ask you to deliver more value, and your teams are stretched to continuously deliver higher performance.

In addition, challenges related to global competition, supply chain issues, rising labor costs, and technology innovations can keep operational teams focused on daily fire-fighting and prevent them from focusing on long-term operational gains.

Committing to a Lean journey of continuous improvement ensures a steady improvement in customer satisfaction, cost reduction, and innovation that delivers higher profitability every year. Enterprise transformation not only delivers improved performance, but also creates begins the cultural change process that is integral to continuous improvement.

We have the operational excellence expertise to deliver significant results in the areas important to you, namely:

- Operating profit / EBITDA gains

- Cash flow improvement

- COGS reduction

- Product quality improvement

- Lead time reduction

- Service level improvement

- Capacity expansion

We examine your business from order-to-cash through a Value Stream Map, identifying sources of waste that limit delivering maximum customer value. Together we map the future state process that will bring breakthrough operational improvements. A series of cross-functional kaizen events deliver the process improvements through intensive one-week working sessions. The new process is implemented by the week’s end, allowing immediate improvement.

Each session leaves the team with specific operational changes that bring early-wins and immediate results. Backsliding is prevented by installing Lean Daily Management which locks in the process improvements that consistently produce improved results.

Typical Lean transformation results include:

- 20-30% productivity gains

- 30-50% added capacity

- 30-70% reduction in lead times

- 30-60% inventory reduction

- 30-50% fewer rejected products

Our Practitioners average over 20 years of real-world experience in solving difficult operational challenges like yours. They are skilled at working together with your operational teams on the change management aspects of continuous improvement, bringing the whole team enthusiastically along in the Lean journey.

We can also work with you to develop a customized Lean Business System. A Lean Business System is the ecosystem that enables sustained profitable growth by deploying strategy, applying Lean and Growth tools, and empowering associates to identify and solve challenging problems. Companies across multiple vertical markets use a Lean Business System to realize double-digit improvements in profitability. It is the enduring evidence of a successful enterprise transformation.

Continuous Improvement Tool Set

While the Lean tools are well-known and fairly common, when, where, and how to apply them to meet objectives requires experience and know-how. Less experienced Lean Practitioners miss the opportunity to apply an optimal mix of tools to achieve the business goals. Our Practitioners have successfully used these tools to achieve significant operational improvements in businesses just like yours.

Value Stream Mapping creates a prioritized, monetized roadmap of improvements to fulfill the future state vision.

5S/Visual Management – A place for everything & everything in its’ place. It’s not just about housekeeping. It’s about achieving the Safety, Quality, Delivery, & Cost benefits of a visually managed workplace.

Standard Work – Design and implement cells/processes to TAKT time (Total Daily Operating Time/Total Daily Requirements). Produce only what’s needed, when it is needed, based on customer demand…the same way, every time.

Sales & Operations Planning (S&OP) – Aligning commercial and operational teams with respect to understanding and managing demand with the intention of providing 100% on-time delivery to customer request, utilizing minimal human and working capital.

Material Pull Systems & Kanban – Downstream processes pull from upstream processes only the amount of goods that are needed, when they are needed. Typically a pull signal (kanban) is employed to the upstream supplier as to what supply is needed to meet demand.

Variation Reduction Kaizen (VRK) – Statistical problem solving and process control in a 5-day kaizen format. Use VRK while executing your kaizen road map when a more sophisticated & comprehensive “green belt or black belt” project is not necessary.

Transactional Process Improvement (TPI) – Lean tools adapted to transactional/support function process improvements in a 3-5 day kaizen format.

Single Minute Exchange of Dies (SMED) – A process for reducing the amount of time it takes to changeover a machine or process. Measured from the last good piece of the previous product to the first good piece of the next product.

Production Preparation Process (3P) – A Lean method, offered in a five day kaizen format, for designing products and processes that better meet customer’s needs. A critical element of any new facility design or relocation to optimize production to best meet customer needs.

Total Productive Maintenance (TPM) – A process designed to completely eliminate unplanned downtime in the manufacturing process thus improving the predictability of safety, quality, delivery and productivity performance.

Root Cause Problem Solving – Get to true root cause(s) of problems through basic, practical problem solving techniques. Utilize Lean/6-Sigma tools to resolve and control to prevent recurrence.

NEXT LEVEL Partners has six sigma Black Belts and Master Black Belts on staff to help you with your more complex process control issues where more sophisticated statistical problem solving methodologies are required.

DMAIC – Five step process (Define-Measure-Analyze-Improve-Control) for understanding and driving out variation from a process.

DFSS (Design for Six Sigma) – Approach of “building quality” and “process control” in at the design, or re-design, stage of product or process development where the expected outcome is at least 4.5 sigma performance.

DOE – (Design of Experiment) is a structured, organized method for determining the relationship between factors (Xs) affecting a process and the output of that process (Ys).

MSA (Measurement System Analysis) – Is an experimental and mathematical method of determining how much the variation within the measurement process contributes to overall process variability.

The most common failure mode of Lean transformations is the ability to sustain the gains…there is a solution! Let NEXT LEVEL Partners work with you and your line leaders to share “the secret to sustainability.”

Daily “Gemba” Walks – Hold that daily production meeting where the production (truth) happens, on the shop floor. Learn how to realize the power of cross functional review and buy-in for what happens on the shop floor every day.

Cell/Area KPI Boards – Capture and track information that truly reflects processing metrics, or the “Key Performance Indicators,” that are important to you and your customers, at the point-of-impact. Learn what to track, how to present the data and who provides the updates.

Managing with Playbooks – Demand can change daily…does that mean we have to re-do our standard work everyday? Absolutely not. Learn how to build thresholds of demand changes into your cellularization & standard work projects and how to adjust labor allocation and operator work content every day, real time, as demand changes.

5S Patrols – 5S and Visual Management levels and expectations should also be standardized. Learn how to institute the necessary controls ensuring accountability lies with those who control it.

A Critical Aspect to Any Sustainable Lean Transformation and a Key NEXT LEVEL Partners Differentiator and Core Ideology. We Do Not Consider Any Client Partnering Engagement a Success Unless This is Achieved. Raise the Leadership Capability and Lean Competency of Your Internal Leadership Team Through Our Proven Knowledge Transfer Methods.

Executive Lean Orientation – A 1 ½ day introduction to lean tools and overview of key lean business system elements and concepts, including some practical exercises to drive key points home. An absolute must early on in your lean transformation journey or following significant restructuring.

Executive Lean Boot Camp – Three to five days of detailed exposure to lean tools, case studies in related fields and key lean business system elements, including comprehensive, hands-on applications. This is not to be mistaken with a few days away from the office at a seminar. Roll-up your sleeves and prepare to immerse yourself in lean.

Lean Leader Boot Camp – Five days of intense lean tools training and application, change management, team building and kaizen management…designed for the lean leaders within your organization that will take your transformation to the next level. Successful transformations require all in key leadership positions to “be on the same page” with respect lean tools application and training techniques. NLP can make this happen for you!

President’s Kaizens – An effective way to share lean techniques and lean leadership best practices, while at the same time creating a competitive “sense of transformation urgency” across the business.

Executive Lean Skills Matrix – A process for ensuring that all executives and functional leaders “walk-the-talk” on thinking, acting and promoting lean throughout the enterprise by raising their personal knowledge of the tools to a meaningful level.

Lean Tool Self Sufficiency & Certification – You’ll want to know that your internal lean resources are fully capable and self sufficient at continuing the efforts long after we disengage.

Operational Excellence is critical to the successful execution of any strategy, but should not itself be the strategy! You don’t “implement” Lean…you “live” Lean. Culture and environment is paramount to tools & techniques.

LEADERSHIP in a Lean Environment – Anyone can buy the tools…leadership makes the difference! Do your middle management and line leaders understand what it takes to truly lead in a lean environment? Set and uphold expectations? Know when & how to delegate, motivate, counsel and discipline? We do…let us show you.

Commitment to Waste Elimination Mindset – All process steps and activities fall into one of two categories, Value Adding or Non-Value Adding. Are you and your team expert at recognizing and identifying the seven deadly wastes in your business processes and functions? The entire enterprise should be.

Commit to the Tools – Develop and/or add to your lean six sigma toolbox by leveraging NLP’s expansive arsenal and Toyota Production System expertise. No master trades person or artist ever created anything of value without the proper tools.

Kaizen Culture and Regimen – Learn and adopt the critical success factors of a true kaizen/continuous improvement culture from those who have delivered in a high performance culture like the one you are creating. Kaizen is not just when it is convenient…it is constant and requires regimen and momentum.

Root Cause Problem Solving – Get to true root cause(s) of problems through basic, practical problem solving techniques. Utilize lean six sigma tools to resolve and control to prevent recurrence. Culturally, you must practice this from the very top of the organization. Manage by facts and data, not impression or emotion.

Self Sustaining – The only true, sustainable transformations are predominantly driven from within. Change is inevitable and a constant. See NLP’s “Lean Daily Management” and “Capability Building and Knowledge Transfer” offerings and make the commitment.

NEXT LEVEL Partners will partner with you to assess your current operating performance, the status of your lean journey to date and develop & implement a customized Lean Transformation Roadmap in support of your overall operating strategy and goals.

Lean Business System Model – A member of NEXT LEVEL Partners leadership team will meet with you and key members of your management team to review NEXT LEVEL Partners “Lean Business System and Transformation Model” to identify elements that may satisfy current needs and/or deficiencies within your own operating system.

Assessment and Gap Analysis – NEXT LEVEL Partners will work with you and members of your team to assess current operating performance to identify areas of crisis and/or dissatisfaction to help focus initial and overall efforts of your lean transformation plans. We will also perform Lean transformation self and collective assessments to identify and prioritize greatest capability gaps.

Customized Lean Business System Engagement – The final deliverable will be a customized, Plan-People-Process, Lean transformation engagement roadmap that outlines the activities, timing, fees, terms and warranty we will provide as your transformation partner.

Expand the concepts of Lean/Sigma to and through your procurement function and supply base. Create a high value Value Stream from which all who support it will benefit.

Sourcing Workshop…Quantifying Supply Chain Opportunities – Participants will analyze current suppliers, identify potential cost and inventory reduction projects, begin developing reverse auctions and/or RFQ packages for each commodity group. Actions can also include identifying, assessing and confirming need/desire for lean/sigma training and/or kaizen events at suppliers to create the ultimate “win-win scenario” with your key suppliers.

“Leaning” Internal Procurement Processes – Productivity, quality and lead time improvements await. Learn and apply Transactional Value Stream mapping (TVSM) and Transactional Process Improvement (TPI) techniques to your purchasing area while driving process improvements that will yield more efficient and effective supply chain management through higher quality, shorter lead times, and lower costs.

Negotiation, Contract Definition and Relationship Structuring – Quote/Bid reconciliation. Eliminate discrepancies between RFQ and bids received. Analyze and compare bids, leverage opportunities for additional negotiation. graphicIdentify and pursue opportunities for optimal inventory pipeline management (i.e. VMI, kanban and pull systems). Implement changes to existing, or new contracts, including those with Low Cost Region (LCR) suppliers. Define and uphold supplier relationship expectations and performance.

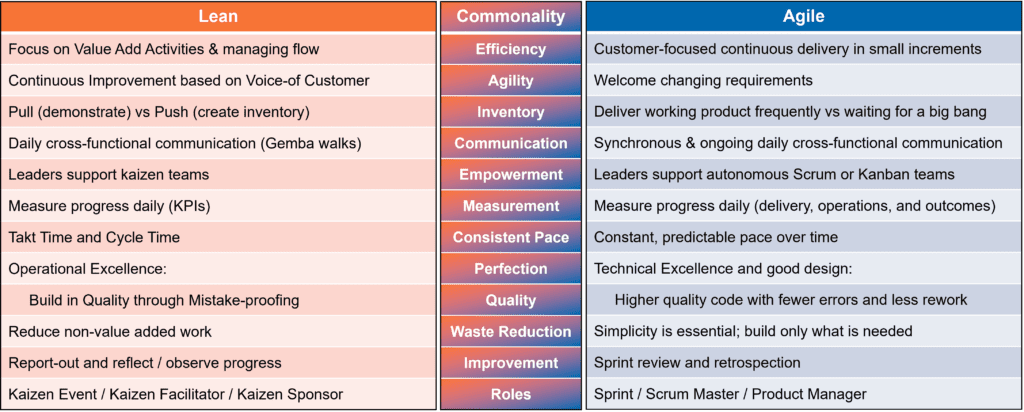

Agile Complements Lean

Lean and Agile are a natural combination for teams looking for rapid process and product improvement. Both methodologies have their roots in the Toyota Production System (TPS). Both Lean and Scrum emphasize using teamwork to create rapid cycles of continuous improvement.

NLP is helping clients using Agile methodologies to incorporate Lean in a complementary way without duplicating efforts. For example, by incorporating Lean Daily Management (LDM) into sprints, Scrum teams can quickly track and measure progress, address problems, and rapidly implement corrective actions.

Agile and Lean principles are closely aligned. When applied together, the result is something greater than either alone!

See the table below for specific comparators of Lean and Agile.

Case Studies Related to Lean Transformation

- All

- Lean Transformation

CASE STUDY: Technology & Industrial

CASE STUDY: Hospitality & Entertainment

CASE STUDY: Manufacturing & Industrial – Agriculture

CASE STUDY: Private Equity and Manufacturing – Medical Devices

CASE STUDY: Rapid growth, multiple acquisitions, and supply chain disruptions

CASE STUDY: Surging seasonal demand, complex product mix, integration issues

CASE STUDY: Hospitality & Entertainment

CASE STUDY: Manufacturing and Packaging

CASE STUDY: Improve lead times and increase capacity

CASE STUDY: Hospitality and Entertainment

CASE STUDY: Healthcare

CASE STUDY: Aerospace and Defense

Contact Us

Manufacturing Practice Leader

1-877-NLP-Lean (657-5326)

NEXT LEVEL Partners®, LLC

2338 Immokalee Road, Suite 415

Naples, FL 34110

Our Experience